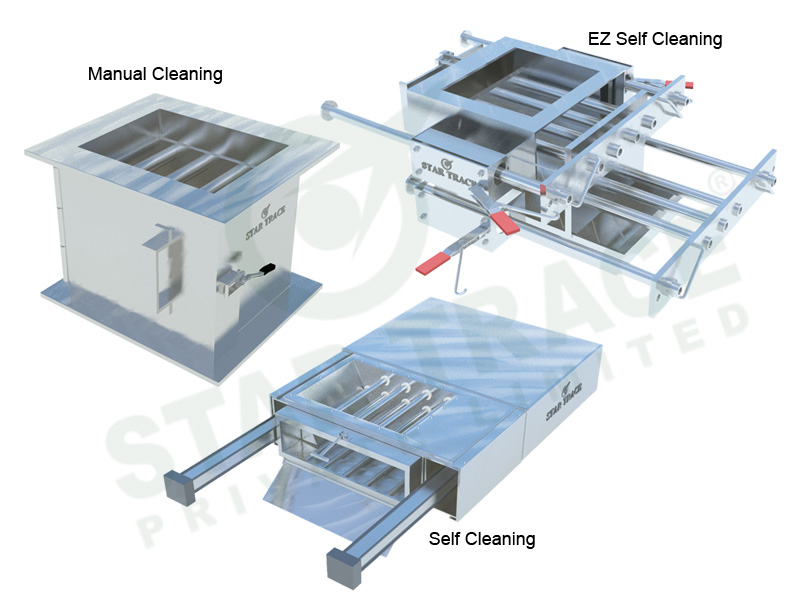

DRAWER MAGNETS

MANUAL-CLEANING DRAWER-IN-HOUSING:

Drawer-in-housings are designed for ferrous metal separation in a wide variety of dry processing applications. The main body of the housing consists of a row, or most commonly rows, of round magnetic tubes that are assembled into drawers. Each row of magnetic tubes are aligned on alternating centers from the row directly above or below it.

As product flows into the top of the housing, it is forced to cascade in a zig-zag pattern from row to row over the magnetic tubes. This cas- cading effect ensures maximum tramp metal capture since the product comes in direct and repeated contact with a magnet as it travels through the housing. As ferrous metal passes through the magnetic field, it is held to the tubes and separated from the product. The metal must now be cleaned from the tubes on a regular basis to prevent buildup and subsequent wash- off back into the product flow.

OPERATION:

The Manual-Cleaning Drawer-in-Housing is designed to simplify the cleaning process to offer flexibility in locating the magnet in high or difficult to reach places, and to encourage frequent and quick removal of collected tramp metal. The Manual-Cleaning housing uses automated technology to initiate the cleaning cycle of the magnetic drawer. When activated, two powerful air cylinders, located on the sides of the housing, remove the magnetic drawer from the product flow area. As the drawer is pushed out, each magnetic tube passes through a seal which wipes the accumulated metal from the tubes. A catch pan is located under the tubes on the front of the housing to collect the metal for analysis or disposal.

SELF-CLEANING DRAWER-IN-HOUSING:

The Self-Cleaning Drawer-in-Housing is designed to simplify the cleaning process to offer flexibility in locating the magnet in high or difficult to reach places, and to encourage frequent and quick removal of collected tramp metal. The Self-Cleaning housing uses automated technology to initiate the cleaning cycle of the magnetic drawer. When activated, two powerful air cylinders, located on the sides of the housing, remove the magnetic drawer from the product flow area. As the drawer is pushed out, each magnetic tube passes through a seal which wipes the accumulated metal from the tubes. A catch pan is located under the tubes on the front of the housing to collect the metal for analysis or disposal.

EZ-CLEAN DRAWER-IN-HOUSING:

Material to be processed enters the top of the housing and flows across the surface of the drum. As the drum shell rotates around the stationary magnetic field, all non-ferrous product which is unaffected by the magnet, falls free from the drum into the cleaned material flow. Any ferrous tramp metal is captured by the magnetic field and is held on the drum’s surface. As the drum rotates, the metal is carried past the diverter and released outside of the magnetic field.