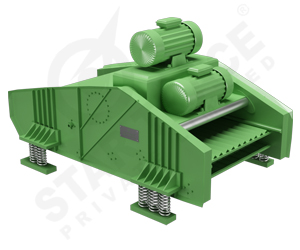

HORIZONTAL VIBRATING SCREENS

INTRODUCTION

Whilst enjoying immense popularity for many years on small horizontal and inclined screens, STAR TRACE is the first company in the world to perfect this simple drive arrangement on linear motion screen. Linear motion screener offers a highly efficient approach to screening. This single development has resulted in tremendous advantages as far as reduced maintenance, compactness and simplicity are concerned. Besides the simplicity of the drive, many other features have been incorporated to provide a machine which is specifically designed for heavy duty applications, long life, and low operating and maintenance costs, at a competitive price. The standard range of screens is presented later in the brochure, and these are normally available on short delivery.

OPERATION:

Linear Motion Screen is equipped with two vibrating motors rotating in opposite directions. This dual motor configuration causes the screen frame to vibrate in a linear or straight-line motion perpendicular to the plane of the motors. Normally, the motors are positioned at an angle of 50 degrees with respect to the screen surface. This result in excellent forward conveyance of oversize particles , even when the screen frame is in an uphill position. Depending upon the application, the screen frame can be position from 10 degrees uphill to 15 degrees downhill. Maximum capacity is achieved in the uphill position, causing the formation of a pool at the feed end of the machine. The head or pressure from the pool increase fluid throughout. The linear motion of the screen frame efficiently conveys the oversize particles out of the pool area where they are then discharged.

FLEXIBLITY:

The screens can be adapted by the factory to meet special requirements regarding plant layout, screen performance and environmental constraints. Specify your particular requirements, or enquire about the range of features, accessories, painting systems and materials of construction currently available. Screens are frequently manufactured in various grades of stainless steel for the chemical industry and protected by special painting systems for severe conditions in the mining industry.

VIBRATORY MOTORS:

These rugged, heavy duty units are exceptionally well insulated against the ingress of dust and water. Their IP 55 protection ensures that the units can operate in wet conditions, such as in washing and dewatering applications. A very generous holding-down bolt design is incorporated.

A common complaint in the past has often been that vibratory motors tended to come loose. A great deal of thought and attention has been given to the fastening design of these motors. When compared with other makes of vibratory motors, the holding-down bolts are often in excess of 50-100% over designed. This, together with stress-relieved and machined surfaces and correctly torched nuts and locknuts, results in an exceptionally secure vibrator fastening system.

When two vibratory motors of the same frequency are fixed to a rigid common base, which is freely suspended, or supported and run in opposite directions to each other, they automatically synchronize to produce a straight line motion. When this motion is applied to a screen, the result is a horizontal action screen suitable for screening, conveying and dewatering of a large variety of products in limited headroom situations.

Linear Motion Drives:

Two Unbalance Motors: These are arranged as a double drive which produce linear vibrations. They are mainly used for medium-sized vibratory screens. Due to linear vibrations, these screens have much lower downwards inclination than those with shaft drives. In special cases can even run without any inclination or with a slight incline.

Exciters: Drive units of this type also produce linear vibrations. They are mainly used for vibrating heavy duty large and very large screens. When more than one exciter is being used in very large screens, vibratory force is uniformly and efficiently transferred from the exciter to the screen. The drive motor of the exciter is a standard foot-mounted motor. The motor torque is transmitted to the exciter either directly via a cardan shaft or indirectly by a v-belt drive or a variable speed gear. The indirect drive allows the user to adjust the rotational speed.

Snubbers - the screen-mounted drive has eliminated the need for snubbers to reduce damage to v-belts and external motors during the large oscillations that normally occur during stopping. Bearing failure is limited to the bearing itself. Particles from a failed bearing cannot circulate in an oil bath and cause possible damage to other bearings and synchronizing gears.

Campactness - screens can be positioned very closely with a minimum of space wastage. A vibrator motor needing reconditioning can easily be exchanged for a standby unit, with a minimum of downtime. Due to the absence of gears and v-belts, the units use less power than conventional drives.

Features

The following are the features of Linear Motion Screens:

- Individually Replaceable Cross Members

Instead of the old type of fabricated screen decks, all STARTRACE screens now incorporate a unique bolted deck arrangement. This means that when wear occurs and deck replacement becomes necessary, only the worn sections are replaced. This is far easier than stripping the entire screen and handling large, heavy fabricated frames. When polyurethane panels are to be fitted to screens up to and including 1 200 mm in width, the panels are located directly into the individually replaceable cross members. The panel and cross member, by direct impingement of the material being screened, is prevented. On larger screens, the cross members can be rubber lined for protection. - Angle Runner System for polyurethane Modular Units

One of the most common complaints with conventional frames for polyurethane panels is the premature wear of the pinholes in the deck, with resultant loosening of the panels. On screens over 1200 mm in width, easily replaceable angle runners are provided to secure the polyurethane panels. With wear, only those runners affected need be replaced, thus reducing costs and downtime. - Flat Bar Runner System for Woven Wire Decks

As in the angle runner system for polyurethane decks, the flat bar stringers are bolted to the cross members, resulting in an easy to maintain deck arrangement. - Automatic Alignment of Tensioning Bolts for side Tensioned woven wire Decks

The illustration show clearly the simplicity of this device. The swivel half cups automatically align the tensing bolts to the exact angle to accommodate various wire thicknesses. - Built-in, Lined Feed Boxes and Discharge Lips

The simplicity of the design of these built in items ensures that feed boxes and discharge lips cannot come loose. - Stress Relieving

The entire welded fabrication is stress relieved to ensure that all residual welding stresses are removed. - Screening Surface

The screens can be fitted with a variety of screening surfaces, such as punched plate, tensioned woven wire, polyurethane or rubber mats, plug-in polyurethane panels, or wedge wire panels.

Applications

- Iron ore jiggling process

- Upgrading the Iron ore

- Iron ore washing plant

- Silica Sand washing plant

- Mineral washing plant

- Mining washing plant

- Trash Screens/Gold Recovery

- Iron ore beneficiation plant

- Hematite ore beneficiation plant

- Hematite jiggling plant

- Magnetite beneficiation plant

- Magnetite jiggling plant

- Garnet sand processing unit

- Garnet sand washy unit

- Breweries

- Carbon Column Safety Screen

- Clay (Grit Removal)

- Digester Clean-up

- Fish and Seafood

- Fruit and Vegetable Processors

- Hog Waste (B.O.D. Reduction)

- Industrial Waste water

- Meat Packaging Plants

- Municipal Waste

- Paper Fiber Recovery

- Petro-Chem Industry

- River Dredging

- Tanneries

- Textiles

- Fruit and Vegetable Processors

- Hog Waste (B.O.D. Reduction)

- Industrial Waste water

- Meat Packaging Plants

Benefits

The advantages of STAR TRACE's Linear Motion Screens is that use of the following equipment has now been rendered unnecessary:

- External drive , with v-belts or cardan shafts.

- Oilbath oscillators, with synchronizing gears and oil leaks.

- Motor support stand, or overhead structure for motor support.

Snubbers - the screen-mounted drive has eliminated the need for snubbers to reduce damage to v-belts and external motors during the large oscillations that normally occur during stopping. Bearing failure is limited to the bearing itself. Particles from a failed bearing cannot circulate in an oil bath and cause possible damage to other bearings and synchronizing gears.

Campactness - screens can be positioned very closely with a minimum of space wastage. A vibrator motor needing reconditioning can easily be exchanged for a standby unit, with a minimum of downtime. Due to the absence of gears and v-belts, the units use less power than conventional drives

KEY BENEFITS:

- High fluid capacity.

- Ideal for dilute slurries and/or low amounts of oversize such as scalping or trash screen applications.

- Appropriate for the removal of grit or other contaminants from viscous slurries.

- Screen openings can range from 3/8inch (10mm) to 400 mesh (38 microns).

- Low headroom requirements.

- Uniform straight-line conveying action.

- High open area polyurethane screen surfaces or various woven wire designs minimize or eliminate screen blinding.